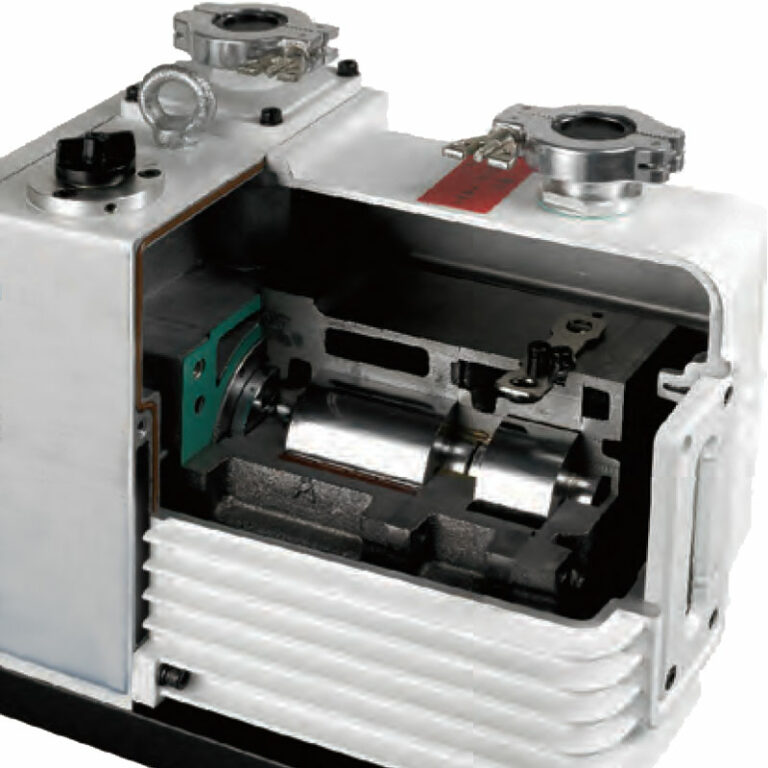

This article outlines the central rotary vane vacuum pump structure that forms the basis of oil-sealed rotary vane vacuum pumps.

Mechanical Powerhouse: Rotary Vane Vacuum Pumps

A rotary vane vacuum pump is an oil-sealed mechanical vacuum pump, which holds a prominent role in vacuum technology. It efficiently extracts dry and certain condensable gases from sealed containers. While equipped with a gas ballast, it can accommodate condensable gases.

However, it’s unsuitable for oxygen-rich, corrosive, or dusty gases. This pump comes in two primary types: single-stage (1-stage) and dual-stage (2-stage).

Volumetric Precision: The Heart of Rotary Vane Pumps

Functioning as a volumetric pump, the rotary vane vacuum pump draws and compresses gas through continuous rotary vane motion within the pump chamber. The expelled gas is directed through an exhaust line.

Key Components and Operation

A rotary vane pump consists of essential components including the stator, rotor, and rotary vanes. The rotor’s eccentric positioning within the stator cavity results in cyclical volume changes.

As the rotor rotates within the stator cavity, spring tension and centrifugal force prompt its end to slide against the pump cavity’s inner wall. This dynamic interplay cyclically alters the volume of the inlet side, drawing in gas, and subsequently reduces the exhaust pipe’s volume, squeezing and expelling the gas through the exhaust line.

Industrial and HVAC Applications

Industrial rotary vane vacuum pumps, known for their robust structure and components, can operate continuously. In contrast, HVAC rotary vane pumps, although sharing the same working principle, don’t require constant operation. These pumps efficiently discharge refrigerants within minutes. It’s essential to avoid running a refrigeration pump for more than 2 hours at a stretch to prolong its lifespan.

Typically, HVAC pumps are designed for around 2 years of service, while industrial pumps can extend their service life to 5 years or more with proper usage and regular maintenance.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China