Handling HVAC refrigerants can be a minefield of regulations and technical challenges. Using the wrong technique not only wastes time but can also lead to hefty fines and environmental damage. I will guide you through the professional techniques that ensure safety, compliance, and efficiency.

The best refrigerant recovery techniques involve using EPA-certified equipment, correctly identifying the recovery method (vapor, liquid, or push-pull) for the specific system size, and adhering to strict safety and environmental best practices to prevent refrigerant release and system contamination.

In my decade of experience with industrial systems, I have learned that handling specialized gases, like refrigerants, requires precision and knowledge. It is not just about getting the gas out; it is about doing it responsibly. In most developed countries, refrigerant recovery is mandatory due to its environmental impact, so understanding these techniques is absolutely essential for any serious technician.

What are the best practices for refrigerant recovery?

Are you just connecting a recovery machine and hoping for the best? This approach risks cross-contamination, equipment damage, and non-compliance. I will outline the professional best practices you must follow.

Best practices for refrigerant recovery include verifying the refrigerant type to prevent cross-contamination, using a clean, properly sized recovery cylinder filled to no more than 80% capacity, using short hoses with low-loss fittings, and carefully monitoring the entire process.

Following best practices is what separates a professional from an amateur. It ensures the job is done safely, efficiently, and legally. These are the non-negotiable steps I always follow.

Verify and Prepare

Before you connect a single hose, verify the refrigerant type in the system. Mixing different refrigerants in a single recovery cylinder makes the entire batch a contaminated, costly waste that is expensive to dispose of. Next, prepare your recovery cylinder. Ensure it is clean, has been evacuated to a vacuum, and is dedicated to the type of refrigerant you are recovering. Crucially, never fill a cylinder beyond 80% of its liquid capacity. This leaves a vapor space for expansion; an overfilled cylinder can rupture dangerously if it heats up.

Connect and Monitor

Use short, large-diameter hoses with low-loss fittings or ball valves. Shorter hoses minimize the amount of refrigerant trapped in the lines and reduce friction, speeding up the recovery process. Once connected, carefully monitor the process. Watch the pressures on your gauges and the weight of the recovery cylinder on a digital scale. Do not just set it and walk away. Monitoring allows you to spot issues, like a drop in flow rate that might indicate a filter clog or a system that has run empty.

Final Steps

Once recovery is complete, properly label the cylinder with the type and amount of refrigerant recovered. Keep accurate records of the recovery process, as this is often required for regulatory compliance. Adhering to these practices protects you, your equipment, and the environment.

Here’s a summary of these best practices:

| Practice | Why It’s Critical | Key Action |

|---|---|---|

| Verify Refrigerant Type | Prevents cross-contamination and costly waste | Use a refrigerant identifier if unsure |

| Use Clean, Dedicated Cylinder | Maintains purity of recovered refrigerant | Label cylinders clearly for each refrigerant type |

| Do Not Overfill Cylinder (80% Rule) | Prevents dangerous hydrostatic pressure/rupture | Use a digital scale to monitor weight |

| Use Short, Low-Loss Hoses | Speeds up recovery, minimizes refrigerant loss | Choose hoses with ball valves |

| Monitor the Process | Ensures safety and efficiency, spots issues early | Watch pressures and cylinder weight |

| Keep Accurate Records | Ensures compliance with environmental regulations | Log date, refrigerant type, and amount |

What are the 3 refrigerant recovery methods?

Are you using the same recovery method for every HVAC system? This one-size-fits-all approach is inefficient and can dramatically slow you down on larger jobs. I will explain the three main methods and when to use them.

The three refrigerant recovery methods are Vapor Recovery, which pulls refrigerant as a gas; Liquid Recovery, which removes it as a liquid first for speed; and Push-Pull Recovery, a high-speed method for transferring large volumes of liquid refrigerant from large systems.

Choosing the right recovery method is key to working efficiently. Each one is suited for different types of systems.

1. Vapor Recovery

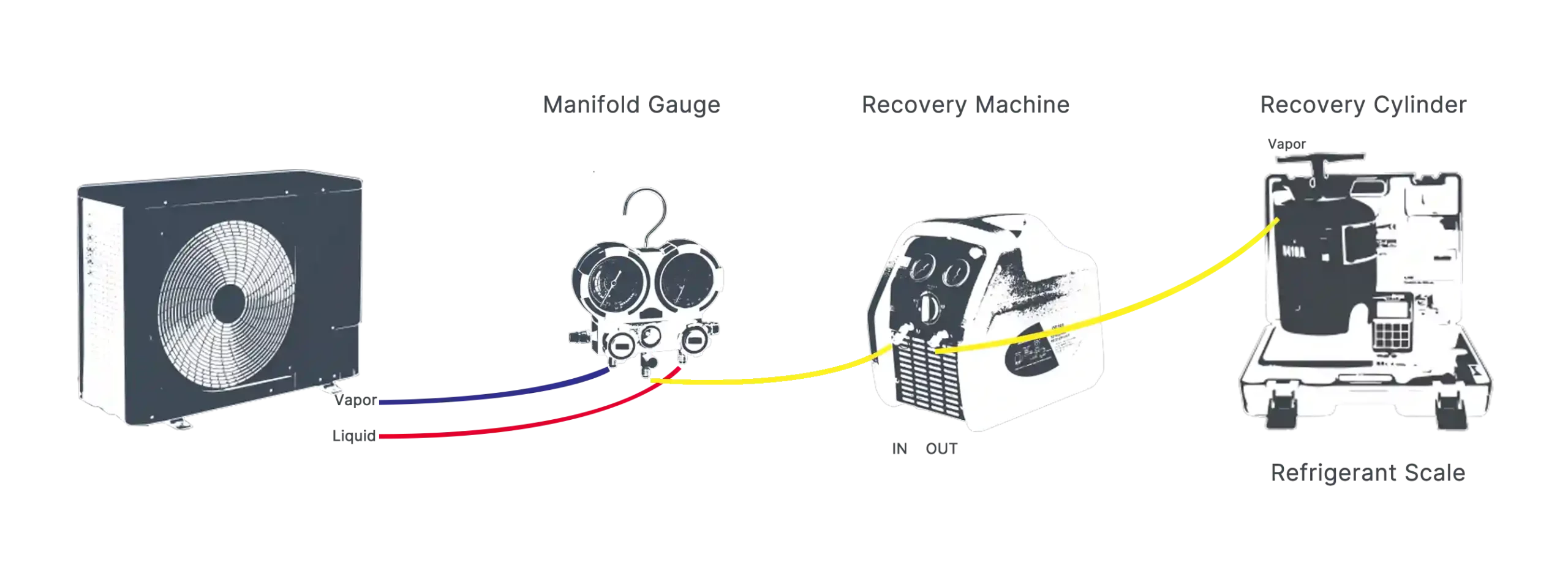

This is the most common and straightforward method. The recovery machine draws refrigerant vapor from the system, compresses it, and condenses it back into a liquid in the recovery cylinder. While it is the slowest method, it is versatile and can be used on almost any system. It is the only method that can pull a system into a deep vacuum to remove every last drop of refrigerant. It is ideal for residential units and smaller commercial systems.

2. Liquid Recovery

For systems containing a larger charge, you can speed things up significantly by removing most of the refrigerant in its liquid state first. This involves connecting your recovery machine to the system’s liquid line service port. Because liquid is much denser than vapor, you can move a large amount of refrigerant mass very quickly. After recovering the bulk of the liquid, you must switch over to vapor recovery to remove the remaining gas and pull the system into a vacuum.

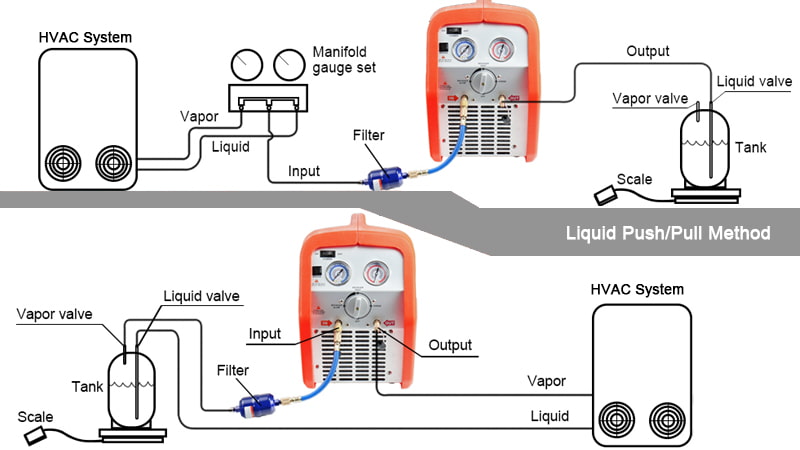

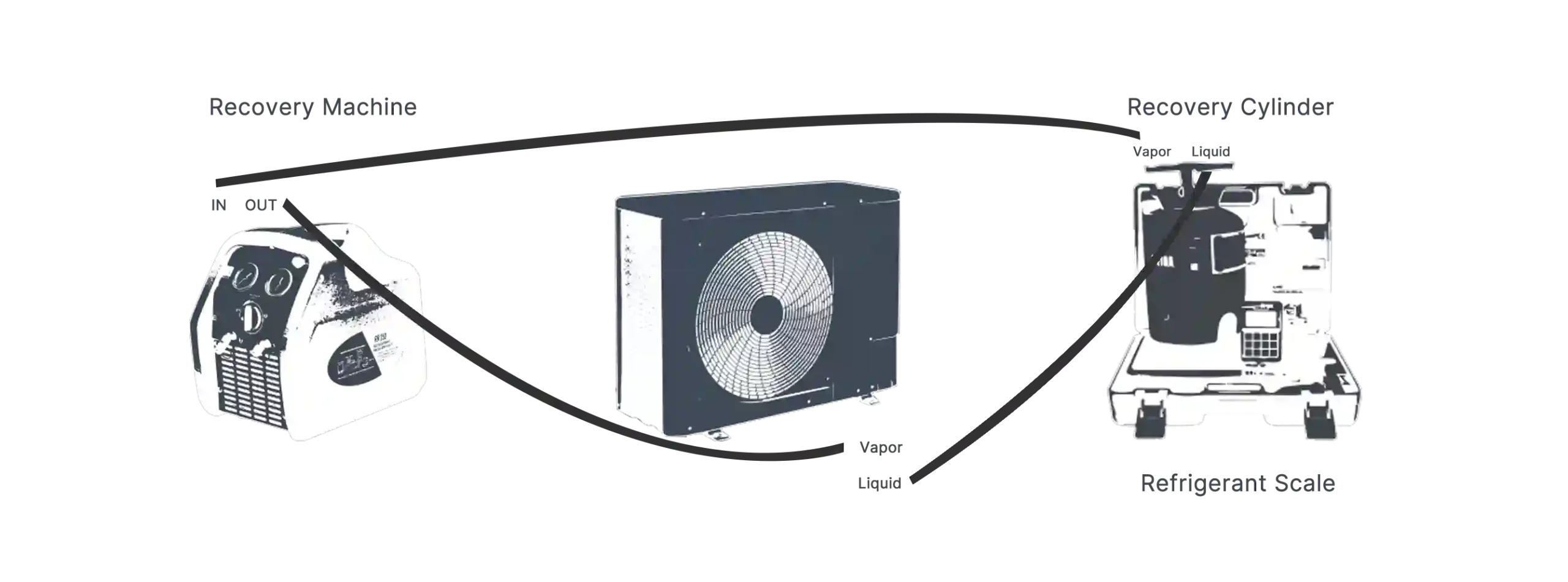

3. Push-Pull Recovery

This is the fastest method for recovering refrigerant from large systems, like commercial chillers, that have both liquid and vapor service ports. It works by pulling vapor from the recovery cylinder, compressing it, and sending it back into the system’s vapor port. This high-pressure gas "pushes" the liquid refrigerant out of the system’s liquid port and directly into the recovery cylinder. It is a highly efficient way to transfer large volumes of liquid. Like liquid recovery, it must be followed by standard vapor recovery to finish the job.

Here’s a quick comparison of the three methods:

| Recovery Method | Speed | Best For | Key Requirement |

|---|---|---|---|

| Vapor Recovery | Slow | Small systems, finishing any recovery job | Standard recovery machine setup |

| Liquid Recovery | Medium-Fast | Systems with a moderate to large charge | Connection to the system’s liquid line |

| Push-Pull | Very Fast | Large systems (>20 lbs refrigerant) | System must have both liquid and vapor access ports |

What is the fastest refrigerant recovery method?

Is slow refrigerant recovery eating into your billable hours on big jobs? Wasting time on-site means less profit and unhappy clients. I will pinpoint the fastest method and explain how it works.

The fastest refrigerant recovery method is the Push-Pull technique. By using the recovery machine to actively push liquid refrigerant out of the system, it can transfer large quantities of refrigerant significantly faster than standard liquid or vapor recovery methods.

When you are working on a large commercial system with 50, 100, or even more pounds of refrigerant, time is critical. In these scenarios, the Push-Pull method is, without a doubt, the champion of speed. I have seen it reduce recovery times from hours to minutes.

The magic of the Push-Pull method is that it uses the recovery machine’s compressor to create a pressure differential that does the heavy lifting. Instead of just "sucking" the refrigerant out, it actively "pushes" it. The process turns the HVAC system and the recovery tank into a closed-loop system. The recovery machine pulls vapor from the recovery tank, pressurizes it, and sends that hot gas into the HVAC system’s vapor port. This incoming pressure forces the dense liquid refrigerant at the bottom of the system out through the liquid port and into the recovery tank. It is like using compressed air to push water out of a tank instead of just letting it drain by gravity.

However, there are important limitations. This method:

- Only works on large systems that have both a liquid and vapor access port.

- Cannot pull the system into a final vacuum. Once all the liquid is transferred, you must reconfigure your hoses and perform a standard vapor recovery to remove the remaining gas.

- Requires careful monitoring to avoid over-pressurizing the system or overfilling the tank.

Here is a simple breakdown of the Push-Pull method:

| Advantages of Push-Pull | Limitations of Push-Pull |

|---|---|

| Extremely fast for large volumes | Requires both liquid and vapor access ports |

| Less wear on the recovery machine | Does not work on smaller systems |

| Works well in cold temperatures | Must be followed by vapor recovery |

What method would best help speed the recovery of a large system’s refrigerant?

Even with the Push-Pull method, are there extra tricks to maximize recovery speed on a massive system? Every minute saved on a big job adds up. I will share some pro tips to accelerate the process even more.

To best help speed the recovery of a large system’s refrigerant, first use the Push-Pull method, then employ techniques like cooling the recovery tank with ice and gently warming the system to maintain a strong pressure differential, ensuring the fastest possible refrigerant flow.

Once you have initiated a Push-Pull recovery, or even if you are doing a standard liquid/vapor recovery on a large system, there are several professional techniques you can use to maintain a high flow rate. It all comes down to managing pressure. Refrigerant flows from an area of high pressure to an area of low pressure. Your goal is to maximize this pressure difference.

Cool the Recovery Cylinder

This is one of the most effective tricks in the book. Place the recovery cylinder in a bucket of ice or cold water. Cooling the cylinder lowers the pressure of the refrigerant inside it. A lower pressure in the tank creates a larger pressure differential between the system and the tank, which "pulls" the refrigerant out much faster. I always keep a bucket handy for large recovery jobs.

Gently Warm the HVAC System

Conversely, you want to keep the pressure inside the HVAC system as high as possible (within safe limits). If the ambient temperature is cool, the pressure of the refrigerant in the system will drop as you recover it, slowing down the process. You can counteract this by safely and gently warming the system’s condenser or receiver with a heat gun or a heating blanket. This keeps the refrigerant pressure up, helping to "push" it out.

Use Optimal Equipment

Always use the shortest possible hoses with the largest possible diameter. Longer, thinner hoses create more friction and restrict flow. Also, ensure the filters on your recovery machine are clean, and remove any Schrader valve cores from the service ports to open up the largest possible path for the refrigerant to flow.

Here’s a checklist for maximizing recovery speed:

| Technique | How It Works | When to Use |

|---|---|---|

| Start with Push-Pull | Moves large liquid volume quickly | On any large system with liquid/vapor ports |

| Cool the Recovery Tank | Lowers tank pressure, increasing pressure differential | Throughout the entire recovery process |

| Gently Warm the System | Keeps system pressure high, increasing differential | When ambient temps are cool or recovery slows |

| Use Short, Large-Diameter Hoses | Reduces flow restriction and friction | Always, especially on large jobs |

| Remove Valve Cores/Check Filters | Creates an unobstructed flow path | At the start of every recovery job |

Final Thoughts

Mastering refrigerant recovery means choosing the right method—Vapor, Liquid, or Push-Pull—and applying best practices. For large systems, leveraging techniques like Push-Pull and managing tank temperature ensures you work safely, efficiently, and in full compliance with regulations.