Maintaining HVAC-R equipment isn’t just about ticking boxes on a checklist. It’s about protecting your investment, avoiding costly downtime, and ensuring every component works with you, not against you. Let’s explore practical, often overlooked strategies that keep systems running smoother for longer.

1. Are You Letting Contaminants Sneak into Your Recovery Systems?

Refrigerant recovery systems are the backbone of HVAC-R workflows, but even minor oversights can sabotage their efficiency. After shutting down a recovery unit, always disconnect and seal tanks immediately. Residual air trapped in the filter-dryer? That’s a silent killer. Purge it thoroughly using a vacuum-rated valve, and never skip inspecting O-rings for micro-cracks. Replace them every 6 months—sooner if you notice stiffness.

Pro Tip: Label tanks with the date of last maintenance and refrigerant type. A simple sticker system prevents cross-contamination.

2. Is Your Vacuum Pump Oil Costing You Time and Money?

Vacuum pumps aren’t “set and forget” tools. Dirty oil doesn’t just reduce efficiency. It turns your pump into a ticking time bomb. After each job, wipe down the exterior with a lint-free cloth to prevent debris ingress. For oil changes, stick to a strict 50-hour runtime schedule (or monthly, whichever comes first). Use only ISO 100-grade oil, and warm the pump to 40°C before draining—cold oil traps moisture.

Avoid This: Don’t mix oil brands. Stick to one manufacturer’s formulation to prevent additive conflicts.

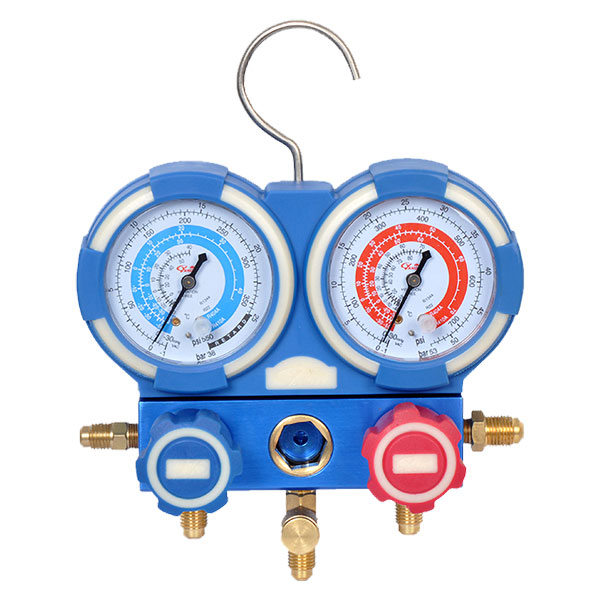

3. Are Your Gauges Lying to You?

A miscalibrated gauge is worse than no gauge at all. Here’s a field-tested method: On a 20°C day, connect your gauge to a sealed cylinder of nitrogen. Compare readings against a trusted digital manometer. If deviations exceed 3%, it’s recalibration time. For analog gauges, gently tap the face to free sticky needles—a trick veterans swear by.

Hidden Risk: Sunlight warps gauge dials. Store them in shaded cases.

4. Does Your Spare Parts Inventory Have Gaps?

Hose gaskets and Schrader cores are cheap, but running out mid-job is expensive. Organize your inventory by failure frequency:

- Tier 1 (Weekly replacements): O-rings, valve cores

- Tier 2 (Monthly): Filter-dryers, pressure switches

- Tier 3 (Annual): Compressor valves, motor bearings

Use clear bins with color-coded labels—green for “in stock,” red for “reorder.”

5. Is Your Team Accidentally Shortening Equipment Lifespan?

Maintenance isn’t a one-person job. Train technicians to:

- Blow out hoses with dry nitrogen after each use (moisture breeds corrosion).

- Store manifolds upright to prevent oil pooling in hoses.

- Log every maintenance action in a shared digital tracker—Google Sheets works fine.

Culture Shift: Reward teams who flag issues early. A “Preventative Maintenance MVP” badge boosts engagement.

The Silent Upgrade Most Businesses Ignore

Older recovery machines waste 15-20% more energy than modern inverter-driven models. While upgrading entire systems isn’t always feasible, retrofitting variable-speed drives to existing compressors can cut energy bills by 12%—with payback in under 18 months.

- Coolink: TOP 3 Global HVAC Vacuum Pump Manufacturer

- Elitevak: Quality Industrial Vacuum Pump Supplier from China