Feeling unsure if your vacuum system is truly performing? An inadequate vacuum level or misjudged performance can lead to process failures and wasted resources. I will show you how to evaluate your system like a seasoned professional.

Evaluating vacuum level and performance like an expert involves using the right gauges for specific pressure ranges, understanding key metrics like pumping speed and ultimate pressure, and consistently monitoring for a stable, leak-free system that meets application-specific requirements.

After a decade immersed in vacuum technology at Elitevak, I have learned that evaluating a vacuum system goes far beyond just looking at a gauge. It is about understanding the subtle signs, using the right tools, and knowing what metrics truly matter for your specific application. Let me walk you through the essential steps I follow to ensure a system is performing optimally.

What is the Most Accurate Way to Measure Vacuum?

Confused by the array of vacuum gauges and their claims of accuracy? Using the wrong gauge can lead to misdiagnosed problems and inefficient operations. I will clarify which gauges offer the best accuracy for different vacuum ranges.

The most accurate way to measure vacuum depends on the pressure range: Capacitance Manometers offer high accuracy for medium to high vacuum, while Hot Cathode Ion Gauges provide precise readings for ultra-high vacuum. Pirani gauges are accurate for rough vacuum, but less so at very low pressures.

Choosing the right vacuum gauge is foundational to accurate measurement. In my experience, using a gauge outside its optimal range is a common mistake that leads to false readings and wasted time. There is no single "most accurate" gauge for all vacuum levels; accuracy is relative to the pressure range you are measuring.

For rough vacuum (atmospheric pressure down to about 10^-3 mbar), Pirani gauges are widely used. They work by measuring the heat loss from a hot filament, which changes with gas density (and thus pressure). They are robust and cost-effective, but their accuracy diminishes as pressure drops below 10^-3 mbar. They are perfect for general industrial applications where high precision at very low pressures is not critical, like in packaging or material handling.

As you move into medium to high vacuum (from 10^-2 mbar down to 10^-5 mbar), Capacitance Manometers (CMs) become the gold standard for accuracy. These gauges measure pressure directly, independent of gas type, by sensing the deflection of a thin diaphragm. Their direct measurement principle makes them incredibly precise and reliable for critical processes like thin-film deposition or calibration. I remember a client who struggled with inconsistent coatings until we advised them to switch from a Pirani to a CM for process control; the immediate improvement in batch uniformity was striking.

For ultra-high vacuum (UHV) applications (below 10^-6 mbar), Ionization Gauges are necessary. Hot cathode ion gauges (like Bayard-Alpert) work by ionizing gas molecules and measuring the resulting ion current. They offer exceptional sensitivity at extremely low pressures, down to 10^-11 mbar. However, they are gas-type dependent and can be affected by contamination or filament burnout. Cold cathode ion gauges (Penning gauges) are also used in UHV but generally have less accuracy than hot cathode types.

Here is a quick overview of common gauges:

| Gauge Type | Pressure Range (mbar) | Measurement Principle | Best For |

|---|---|---|---|

| Pirani | 1000 to 10-3 | Thermal Conductivity | Rough Vacuum |

| Capacitance Manometer | 10 to 10-5 | Direct Pressure | Medium to High Vacuum |

| Hot Cathode Ion | 10-3 to 10-11 | Ionization Current | High to Ultra-High Vacuum |

Understanding these differences is key to proper system evaluation and ensures you trust your readings.

How Can You Effectively Check Your Vacuum Level?

Are you pulling vacuum but unsure if you are hitting the target? Just watching a needle move is not enough. I will show you how to effectively verify your vacuum level for optimal performance.

To effectively check your vacuum level, use a calibrated digital micron gauge connected directly to the vacuum system, ensuring it is within the gauge’s optimal range. Monitor the pressure readings over time to observe the pump-down curve and confirm the system holds a stable vacuum without significant leaks or outgassing.

Checking your vacuum level effectively involves more than just a quick glance at a gauge. It requires a systematic approach to ensure accuracy and to diagnose potential issues. From my firsthand experience, many issues stem from incomplete or incorrect vacuum level verification.

The first step is always to use the appropriate gauge. As discussed, a digital micron gauge is essential for deep vacuum levels (below 1 Torr / 1000 microns). Analog gauges on manifold sets are generally not sensitive enough for true vacuum verification. Connect your gauge as close as possible to the point of interest in the system, ideally at the chamber or main line, to get an accurate reading of the actual vacuum being achieved.

Next, you need to monitor the pump-down curve. As your vacuum pump operates, watch how quickly the pressure drops. A healthy system and pump should show a steady, continuous decline in pressure. If the pressure drops quickly initially but then plateaus much higher than expected, it could indicate a significant leak, excessive outgassing, or a pump that is not performing efficiently. I remember a lab struggling with inconsistent results; we found their pump-down curve flattened out too high, indicating a persistent leak they had overlooked.

Once the target vacuum level is reached (e.g., 250 microns for AC systems, or much lower for scientific applications), isolate the pump from the system and monitor the pressure rise. Close the valve to the vacuum pump, leaving the gauge connected to the system. A perfectly leak-free system should show very little to no pressure rise over a set period (e.g., 15-30 minutes). A significant pressure rise indicates a leak somewhere in the system, or excessive outgassing if the system is "dirty" or contains volatile materials. This simple decay test is invaluable for diagnosing problems. If the pressure rises quickly, you have a major leak. If it rises slowly and then stabilizes, it might be outgassing. Regularly checking these factors helps ensure your system is performing as it should.

What Metrics Define Vacuum Pump Performance?

Beyond just vacuum level, what truly defines a vacuum pump’s capability? Overlooking critical metrics means you might select the wrong pump, leading to inefficiencies. I will demystify the key performance indicators.

Vacuum pump performance is defined by key metrics including ultimate pressure (lowest achievable vacuum), pumping speed (volume of gas moved per unit time), and throughput (mass flow rate). Understanding these allows you to match the pump’s capabilities precisely to your application’s gas load and desired vacuum level.

When we talk about a vacuum pump’s "strength" or "performance," we are referring to specific technical metrics. Simply asking "how strong is it?" is not enough. As an expert, I always look at these three crucial factors:

First, Ultimate Pressure (also called base pressure or blank-off pressure) is the lowest pressure a vacuum pump can achieve when operating in a closed system. This is a critical indicator of a pump’s quality and its suitability for deep vacuum applications. If your process requires 10^-5 mbar, you need a pump with an ultimate pressure rating significantly lower than that, ideally 10^-6 mbar or better, to give you some headroom. A common mistake is buying a pump whose ultimate pressure barely meets the requirement, which leaves no margin for error or system outgassing.

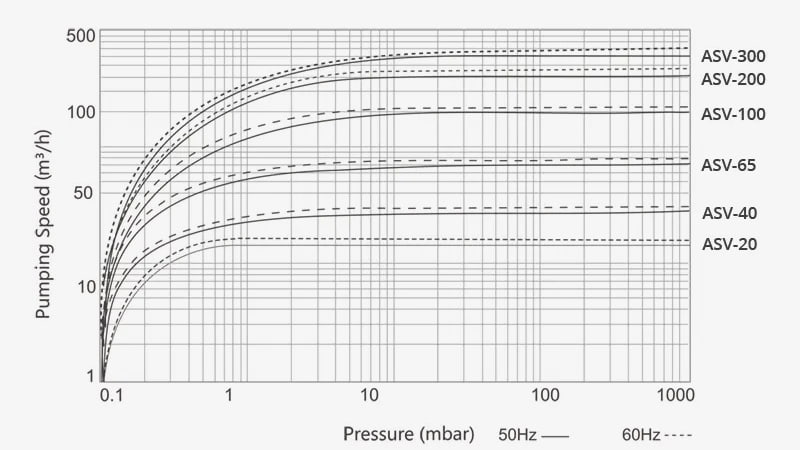

Second, Pumping Speed (often measured in liters per second (L/s) or cubic feet per minute (CFM)) describes the volume of gas that a pump can remove from a system per unit of time at a given pressure. This metric determines how quickly you can achieve your target vacuum level (pump-down time) and how effectively the pump can handle gas loads during the process. If your process has a high gas load (e.g., rapid outgassing, continuous gas introduction), you need a pump with a high pumping speed at your operating pressure. A common issue is a pump with good ultimate pressure but insufficient speed for the application’s gas load, leading to slow pump-down or inability to maintain vacuum during operations.

Third, Throughput is the amount of gas (mass flow rate) that a pump can move over time at a specific pressure. It is often calculated as pumping speed multiplied by pressure (Q = S x P). Throughput is especially important for processes that involve a continuous flow of gas into the vacuum system, such as sputtering, chemical vapor deposition, or vacuum drying with significant solvent evaporation. Matching the pump’s throughput to your process gas load ensures the pump can maintain the desired vacuum level under dynamic conditions.

Here’s how these metrics interrelate:

| Metric | Definition | Why it Matters |

|---|---|---|

| Ultimate Pressure | Lowest achievable vacuum in a closed system | Dictates the deepest vacuum possible for your process |

| Pumping Speed | Volume of gas removed per unit time at pressure | Determines pump-down time and response to gas loads |

| Throughput | Mass flow rate of gas removed | Important for processes with continuous gas loads |

Understanding these metrics helps you choose a pump that matches your system’s exact needs, ensuring efficient and reliable operation.

What is the Ideal Vacuum Level for Your Application?

Is a "perfect" vacuum always your goal? Chasing unnecessary vacuum levels wastes energy and money. I will show you how to identify the ideal vacuum level that perfectly suits your specific application’s needs.

The ideal vacuum level for an application is the minimum required pressure that achieves the desired process outcome efficiently and cost-effectively, without over-specifying. This depends on factors like gas type, cleanliness needs, temperature, and material properties, often categorized into rough, medium, high, and ultra-high vacuum ranges.

The concept of a "perfect" vacuum is mostly theoretical – a space entirely devoid of matter. In practical applications, the "ideal" vacuum level is the one that allows your specific process to function optimally and efficiently, without going overboard. I have consistently found that over-specifying vacuum levels is a common pitfall, leading to unnecessary expense and complexity.

Defining the ideal vacuum level starts with a deep understanding of your application’s requirements. What precisely are you trying to achieve with vacuum?

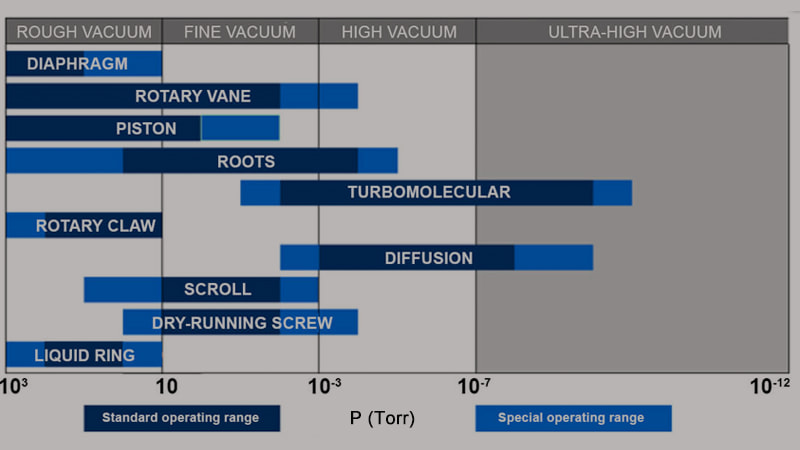

- Rough Vacuum (e.g., 1000 mbar to 1 mbar): This range is suitable for general industrial processes like vacuum packaging, degassing of liquids, drying, material handling (e.g., vacuum lifters), and roughing for higher vacuum systems. It is relatively easy and inexpensive to achieve.

- Medium Vacuum (e.g., 1 mbar to 10^-3 mbar): Often used for distillation, freeze-drying (lyophilization), impregnation, and some analytical instruments. Here, you are starting to remove significant amounts of water vapor and achieving conditions that prevent atmospheric effects.

- High Vacuum (e.g., 10^-3 mbar to 10^-7 mbar): This range is critical for processes like thin-film deposition (e.g., sputtering, evaporation), electron microscopy, and certain types of leak detection. At these pressures, mean free path of molecules becomes long, allowing for "line of sight" processes.

- Ultra-High Vacuum (UHV) (e.g., 10^-7 mbar to 10^-11 mbar and lower): Essential for surface science research, semiconductor manufacturing, and particle accelerators. At UHV, even molecular monolayers can be controlled, and gas-surface interactions are minimized.

Beyond just the pressure number, consider gas type, cleanliness needs, and temperature within your system. For instance, processes with aggressive gases might demand a specific vacuum level and specific pump materials, while applications sensitive to contamination (like in electronics) require oil-free pumps and very deep vacuum to minimize outgassing. My experience confirms that matching the vacuum level precisely to the process prevents energy waste and maximizes both efficiency and output quality. Don’t chase a "perfect" vacuum if a "good enough" vacuum does the job perfectly for your needs.

Final Thoughts

Evaluating vacuum level and performance like an expert demands understanding specialized gauges, key metrics like pumping speed and ultimate pressure, and matching the ideal vacuum level to your precise application needs for optimal system efficiency and longevity.