In the pharmaceutical production sector, manufacturers operate with four distinct categories or combinations: bulk products, semi-finished goods, active ingredients, and FDA-approved pharmaceuticals. The production of bulk drugs and semi-finished products predominantly falls under the purview of fine chemical companies.

Pharmaceutical production encompasses a diverse range of vacuum separation processes, including rough vacuum extraction, low vacuum retrieval of organic solvents, high-temperature-sensitive material high vacuum distillation, solid impurity elimination through vacuum filtration, and vacuum drying of powder intermediates or final products. In each of these processes, vacuum equipment plays a vital role. The majority of rough vacuum equipment comprises water ring pumps, rotary vane pumps, and rotary piston vacuum pumps.

Outlined below are the four primary applications of vacuum pumps in the pharmaceutical industry:

1. Distillation

Distillation is a pivotal process that separates layers or components with distinct temperatures, pressures, compositions, and phases. As the distillation tower approaches equilibrium, each component attains a unique concentration and can be isolated from the mixture. The distillation tower provides the requisite pressure to facilitate the separation of diverse liquid components by manipulating vacuum levels and temperature.

Water ring vacuum devices, for instance, effectively eliminate non-condensable substances, water, and light hydrocarbons from the system. They also condense gases discharged from the apex of the distillation tower, redirecting the liquid back into the tower for further separation. This method finds common application in the refinement of fatty acids, single-component glycerol hydrochloride, vitamins (A, E), oils, fats, waxes, insecticides, plasticizers, among other compounds.

2. Crystallization

Crystallization revolves around the evaporation and cooling of a supersaturated liquid to generate crystals that are convenient for handling, storage, and commercialization. Vacuum pumps emerge as the preferred choice for this process, as they effectively control evaporation and cooling rates at all pressure levels and reduce the boiling point of the liquid, ultimately cutting costs.

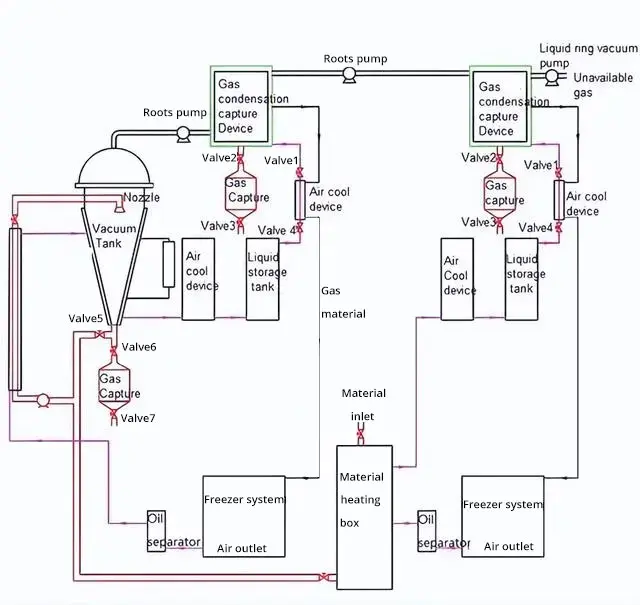

Water-ring Roots unit for Distillation-crystallization process

3. Drying

Drying constitutes a cost-effective, low-temperature procedure. By reducing pressure, it drives the evaporation of liquids from solids, safeguarding the integrity of biological components and active ingredients against degradation, destruction, or oxidation.

Drying protocols for medical and biological products, inclusive of solvent and water removal, necessitate a final vacuum level of less than 1 torr. Following this procedure, a granular product remains, ready for compression into tablets, with low moisture content, ensuring prolonged preservation.

4. Vacuum Degassing

Degassing is the process of purging dissolved or residual gases from liquids or products. Vacuum equipment excels in this regard, ameliorating physical properties and enhancing product quality for subsequent processing. This, in turn, mitigates the risk of cross-contamination or corrosion. Applications include deoiling for heightened purity (hydrocarbons, insulating oil, turbine oil, brake fluid, etc.), paint stripping to remove excess gases that may lead to hardening or deterioration, and polymer degassing in extruders to yield superior quality, devoid of air bubbles.

In essence, vacuum pumps are the unsung heroes that revolutionize pharmaceutical production. Their precision and efficiency in manipulating pressure levels, temperature, and composition pave the way for breakthroughs in drug development and production. Whether isolating potent active ingredients or ensuring the purity of final formulations, these pumps set the stage for excellence.

- Coolink: TOP 3 Global HVAC Vacuum Pump Manufacturer

- Elitevak: Quality Industrial Vacuum Pump Supplier from China