The electric vehicle (EV) industry is rapidly growing as people shift towards sustainable and environmentally-friendly modes of transportation. Among various innovative technologies used in this industry, vacuum technology is particular and indispensable to improve the performance, efficiency, and safety of EVs.

1. Li-ion battery manufacturing

Vacuum technologies are used in the manufacturing of Li-ion batteries, the key part for EV to ensure that the process is contamination-free and to optimize the performance of the battery cells. Dry screw pumps play a critical role in this process.

2. Electric motor assembly

Another key component of EV is electric motor. Vacuum impregnation of electric motor windings improves the insulation properties and increases their lifespan.

In the vacuum impregnation process, a vacuum pump is used to remove air and vapor from the voids in the windings before impregnation with resin. The most commonly used vacuum pumps for this process are oil-sealed rotary vane pumps.

3. Heat treatment of metal components

Vacuum heat treatment is an important process used in electric motors, such as rotor shafts and stator laminations.

The process involves heating the components in a vacuum chamber, which prevents oxidation and contamination. It improves the mechanical properties and durability of heated components. This process is also used in the production of battery materials and power electronics.

Diffusion vacuum pump and Roots pump are two main types used for the vacuum heat treatment.

4. Vacuum coating

Vacuum coating is a process that involves applying a thin film of material onto a substrate in a vacuum environment.

In the EV industry, vacuum coating is used primarily for two purposes: improving the performance and durability of the EV components and enhancing the aesthetics of the vehicle.

Coatings are applied to the battery electrodes to improve their conductivity and extend their life. Coatings are also applied to the wheels, trim, and other exterior components to give them a shiny and metallic appearance.

For most vacuum coating applications, rotary vane pumps are the reliable, cost-effective option. Other types of vacuum pumps, such as the dry screw pump and the turbo molecular pump, are also used in some specialized vacuum coating applications.

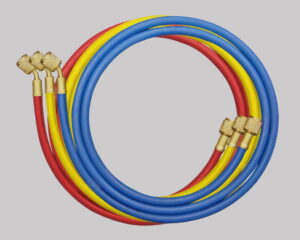

5. Air conditioning systems

The air conditioning system of an EV is similar to that of a traditional vehicle, consisting of a compressor, condenser, evaporator, and expansion valve.

During the manufacturing process, a vacuum pump is used to evacuate the air and vapor from the refrigerant lines and components before the refrigerant is added. This process is known as evacuation and is essential to ensure that the air conditioning system works efficiently and effectively.

Rotary vane pumps are commonly used in EV air conditioning systems due to their compact size, efficiency, and reliability.

6. Vacuum exclusion and forming

Vacuum exclusion and forming are particularly used in the production of some components, such as carbon fiber-reinforced polymer (CFRP) parts, to achieve high strength and low weight.

Battery cell components, some body and chassis components and various interior components, such as dashboard components are produced in this process.

The most common pump type is rotary vane vacuum pump.

7. Brake systems

Vacuum technologies are used in the production of vacuum brake boosters, which provide additional force to the brake pedal and enhance the braking performance.

The vacuum pump used in the brake system is typically an electric vacuum pump. It is a compact and efficient pump that uses an electric motor to create a vacuum inside the brake booster.

8. Tires manufacturing

Vacuum vulcanization technology is a process used in tire manufacturing to improve the quality and performance of the tire. The process involves placing the uncured tire in a vacuum chamber, evacuating the air to create a vacuum, and then heating the tire to cure it.

The use of vacuum in the vulcanization process has several benefits. First, it removes air and moisture from the tire, which can cause defects such as blisters and voids. Second, it improves the distribution of heat and pressure, resulting in a more uniform cure and better tire quality. Third, it reduces the curing time, which increases productivity and reduces costs.

Two types of vacuum pumps commonly used in tire vulcanization are rotary vane pumps and dry screw pumps.

9. Electric vehicle charging systems

Vacuum technologies are used in some specialized charging systems for electric vehicles, such as fast chargers or high-power chargers. In these systems, vacuum contactors are used to connect and disconnect the charging cables and connectors, ensuring a reliable and efficient transfer of electrical energy.

Vacuum contactors are specialized electrical switches that use a vacuum to interrupt or establish an electrical connection. They offer several advantages over traditional electrical switches, including faster switching speed, higher reliability, and longer lifespan. Vacuum contactors are also more compact and lightweight than their electrical counterparts, making them an ideal choice for high-power applications.

The most common type of vacuum pump used in this application is a rotary vane pump.

10. Vacuum brazing of aluminum and copper components

Vacuum brazing is a process used in the manufacturing of various components for electric vehicles, such as batteries, motors, and power electronics. This process involves joining two or more metal parts together using a brazing filler metal that has a lower melting point than the base metals being joined. The brazing process is carried out in a vacuum environment to prevent oxidation and contamination of the metal parts being brazed, resulting in a strong and durable joint.

One important application of vacuum brazing in electric vehicles is the production of battery packs. Vacuum brazing is used to join the battery cells together and to attach the electrical contacts to the cells. This process ensures that the battery pack has good thermal conductivity, which helps to dissipate the heat generated during charging and discharging. It also provides a strong and reliable connection between the cells and the electrical contacts, which is critical for the proper functioning of the battery.

There are several types of vacuum pumps that can be used for this process. They’re rotary vane pumps, scroll pumps, and turbo pumps.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China