Usually you may find some vacuum oil that accompanies the new vacuum pump for first time use. If there’s no vacuum oil, or it’s the time to change vacuum pumps oil, you need to know how to select the type of the genuine oil or its equivalents. The key point is to check the vacuum oil viscosity.

What is viscosity of vacuum pump oil?

Viscosity is resistance of a fluid to movement, which affects the two main functions of vacuum pump oil, i.e. lubricating and sealing. If viscosity is high, oil lubricating becomes less. When it’s too low, then vacuum oil cannot seal.

How to select oil with appropriate vacuum oil viscosity?

1) Low viscosity conditions:

- Vacuum pumps with high rotational speed. Vacuum pumps use mostly 2-pole motor with 2800 rpm, or 4-pole motor with 1400 rpm.

- Vacuum pumps with high line speed of rotor movement

- Vacuum pumps with high processing precision or small clearance between friction parts

2) High viscosity conditions:

In contrast to the above, it’s recommended to use vacuum oil with higher viscosity. It’s better to have high vacuum oil viscosity in case the pump works under high temperature but without water cooling circulation.

Viscosity grades and equivalents

Normal viscosity for vacuum pump oil is 32, 46, 68, 100 and 150 cSt (mm2/s) at 40°C. The vacuum oil with 32 or 46 cSt is usually used for Roots pumps and screw pumps. The rotary vane vacuum pumps use oil with 46, 68 cSt or higher.

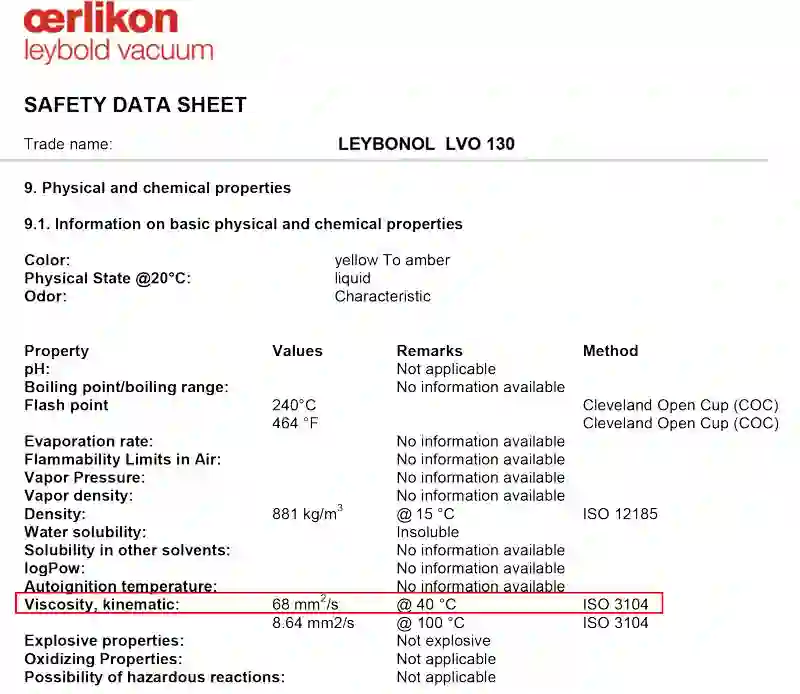

In general, you may find viscosity in the MSDS (Material Safety Data Sheet) provided by the oil manufacturer. An example:

Generally speaking, it’s the best to use genuine oil provided by the vacuum pump manufacturer. However, it’s not possible, or too expensive to get it sometimes. In such case, it’s considerable to choose equivalent oils based on kinematic viscosity.

For instance, if the viscosity of the genuine oil is 68 cSt, you may choose Leybold LVO-130 or Edwards Ultragrade 19.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China