Introduction

Much like their rotary vane counterparts, rotary piston vacuum pumps are volumetric pumps with a wide range of applications and operational parameters. Industries such as aerospace, vacuum impregnation, vacuum coating, and metal drying benefit from their capabilities.

Owing to their substantial capacity, rotary piston pumps find extensive use in large-scale vacuum systems. These pumps, like many others in the field, come in two fundamental types: single stage and dual stage.

Small-sized single-stage pumps typically maintain an ultimate pressure of no more than 0.6 Pa, while their larger counterparts do not exceed 1.3 Pa (with gas ballast closed). Dual stage pumps achieve an ultimate pressure of no more than 0.06 Pa (with gas ballast closed). Notably, rotary piston vacuum pumps with a pumping speed greater than 150 L/s are predominantly single stage.

How the Rotary Piston Vacuum Pumps Work

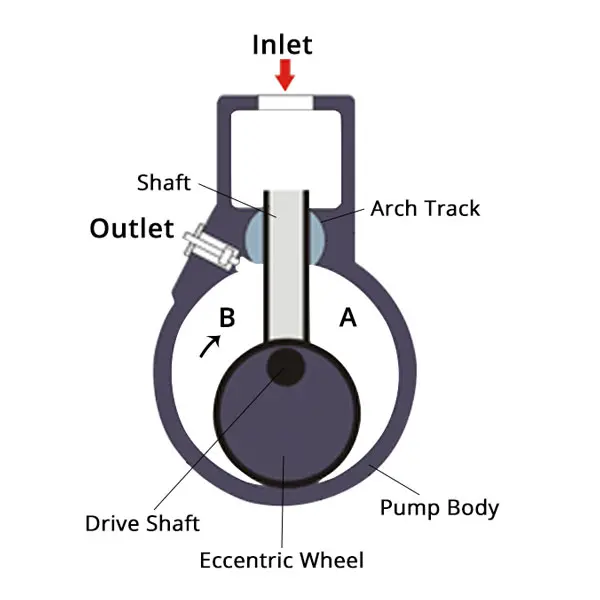

The rotary piston pump comprises key components such as the pump body, eccentric wheel, piston assembly, and arch track. Its chamber is divided into Section A and Section B by the piston.

As the drive shaft undergoes clockwise rotation, Section A’s volume expands, resulting in decreased pressure. Gas is drawn into the chamber through the inlet and shaft. Simultaneously, the piston shifts leftward until Section A’s volume reaches its maximum, at which point the inlet is sealed.

Concurrently, Section B’s volume diminishes, leading to gas compression. Once the pressure in Section B surpasses atmospheric levels slightly, the gas is expelled through the outlet, creating a vacuum.

Challenges: Vibration and Noise

Rotary piston pumps commonly exhibit significant vibration due to the complexity of achieving complete balance between the eccentricity of the rotating mass and inertia forces. Consequently, most models are designed to operate within a range of 350 – 600 rpm.

Through specialized design, ZCVac rotary piston pump addresses the challenges of vibration and noise, offering a significant improvement. For more information, click HERE.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China