This article is to Introduce vacuum oil emulsification.

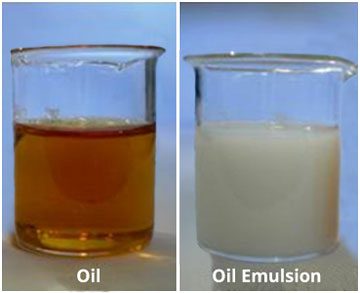

The emulsification of vacuum pump oil occurs quite often during operation of oil-sealed vacuum pumps, in particular in the applications of pharmaceutical, food and ceramic industries. This phenomenon is the result of the mixing of two or more typically immiscible liquids, which occurs due to the presence of surfactants. Emulsification is a frequent problem associated with oil-sealed vacuum pumps, and it can have serious consequences. Therefore, it is essential to understand the underlying causes and potential hazards of this issue.

Causes of Vacuum Oil Emulsification

- Reduced vacuum pump performance: Emulsified oil can reduce the efficiency of the vacuum pump and cause it to lose suction power.

Corrosion of pump components: The emulsified oil can corrode the internal components of the vacuum pump, leading to premature wear and failure.

Contamination of vacuum chamber: Emulsified oil can contaminate the vacuum chamber, leading to product quality issues and potential safety hazards.

Increased operating costs: Emulsified oil requires more frequent changes and can be more difficult to dispose of, leading to increased operating costs.

Hazards of Emulsification

- Water contamination: vapory air may enter the vacuum pump through leaks or condensation, and can react with the oil to form an emulsion. Water contamination is more likely to occur in humid environments or when the pump is not used frequently.

- Corrosive gases: Corrosive gases may be pumped into the vacuum chamber during the pump operation. The corrosive gases will corrode the internal metal components and then chemically react with the vacuum pump oil.

High operating temperature: When the operating temperature of the vacuum pump is high, the oil can break down and lose its lubricating properties. This can cause the oil to emulsify and form a thick, milky solution.

Improper maintenance: Failure to maintain the vacuum pump properly can lead to a build-up of contaminants in the oil, which can cause it to emulsify. Regular oil changes and proper cleaning of the pump helps prevent this problem.

Solutions of Emulsification

- Choose the right oil: Using vacuum pump oil with low viscosity and anti-emulsification additives can help prevent emulsification. It is essential to select the appropriate oil type and grade based on the application and operating conditions.

Gas ballast: The gas ballast feature in a vacuum pump can help prevent emulsification by introducing a controlled amount of air into the pump. This air can help carry away any vapors or moisture that may be present.

Proper maintenance: Regular maintenance and cleaning of the vacuum pump can help prevent the build-up of contaminants in the oil, which can lead to emulsification. It is important to follow the manufacturer’s recommended maintenance procedures.

Oil separation: Using oil separation equipment, such as oil separators or oil mist eliminators, can help prevent oil emulsification by removing any entrained oil from the exhaust gases.

Monitor pump operation: Regular monitoring of pump operation can help detect any potential issues early on and prevent the emulsification of the vacuum pump oil. This can include monitoring the operating temperature, vacuum level, and oil condition.

Click to learn more about Vacuum Oil Types.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China