Electric motor is one of the key components for the vacuum pump. To use the pump properly, it’s necessary to have some knowledge about the vacuum pump motors.

Power supply for vacuum pump motors in the factories

The voltage for 3-phase is rated at 380 V in many countries. In order to prevent power loss in transmission lines, the voltage supplied to the factory transformer is generally set at 400 V.

The general power supply in the factory is a three-phase four-wire system, which is compatible with three-phase voltage for production and single-phase voltage for lighting.

For instance, a 3-phase motor can be connected to three phase wires, and single-phase load such as lighting and home appliances can be connected to one of the phase wires and zero wire. For some special equipment such as welding machines, two-phase power supply can be achieved by connecting to two phase wires.

In many countries, the frequency for 3-phase power is 50Hz. It means the voltage changes 50 times per second. In some other countries, the frequency of the alternating current is 60Hz.

Motor wiring connection

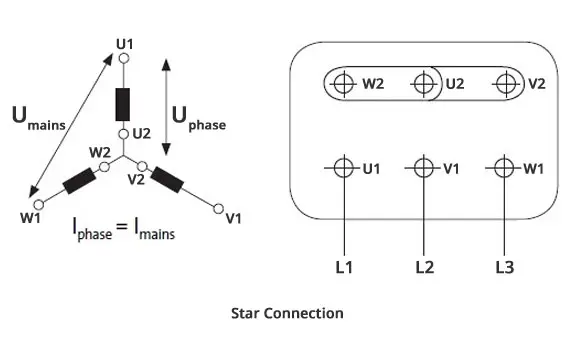

AC motors are used in rotary vane vacuum pumps, including single-phase and three-phase asynchronous motors. Generally, star connection (220/380V) is used for motors with power of 4 kW or less. Delta connection (380/660V) is mostly for motors with power above 4 kW. In principle, wiring must be done according to the connection diagram on the motor nameplate.

The rotation direction of the AC motor is related to the phase sequence. In case the phase sequence is incorrect, the rotation of the vacuum pump will be wrong, which results in damage of the pump.

How to select motor for the vacuum pump

If it is known that voltage=380 V, current=9 A, power factor=0.81 and motor efficiency=0.85,

Then shaft power = 1.732 * 380V * 9*0.81/1000 = 4.798 kW

The required motor power= 4.798 kW / 0.85 = 5.64 kW.

Since there’s no standard motor with power of 5.64 kW, you have to choose the closest one that is 5.5 kW.

The calculation and selection result may vary if the motor efficiency differs from 0.85.

Preventive measures

The vacuum pump shall operate under ambient temperature below 40°C, and make sure the room is well ventilated.

To ensure the motor works properly, check carefully the rated voltage, frequency and other data on the nameplate. If it’s difficult to confirm the wiring, start connection is recommended. Start the pump with no load and check the current by increasing the load gradually.

Make sure all electrical connections are performed by a professional electrician and regular maintenance is done according to the manual instructions.

Coolink, a TOP 3 Global HVAC Vacuum Pump Manufacturer & Quality Industrial Vacuum Pump Supplier from China