Picking the perfect manifold gauges for HVAC/R involves considering the refrigerant types you work with, the gauge’s accuracy, port configuration (2, 3, or 4), and durability. Digital gauges offer more precision and data logging, while analog sets are cost-effective and robust.

How Do I Select the Right Manifold Gauge Set for My Specific Needs?

Selecting the right manifold gauge set means evaluating the refrigerants you service, required pressure ranges, analog vs. digital preference, and hose compatibility. Consider sets designed for specific refrigerant types (e.g., R-410A) to ensure accurate readings and proper connections.

Selecting the right manifold gauge set is about aligning the tool with your typical work. The most critical factor is the refrigerant type. Modern HVAC/R systems use various refrigerants, each with different pressure-temperature characteristics. Older R-22 systems have different pressure ranges than newer R-410A systems. A gauge set designed for R-22 will not accurately read R-410A pressures, as their pressure scales are different, leading to misdiagnoses. Some gauges are “universal” for multiple refrigerants, but always check their specific scales. I always tell my clients to choose gauges with pressure scales and temperature charts appropriate for the refrigerants they most commonly encounter.

Next, consider analog versus digital gauges. Analog gauges are robust, require no batteries, and are generally less expensive. However, they can be less precise, prone to parallax errors (where the viewing angle affects the reading), and may require more frequent manual calibration. Digital manifold gauges, on the other hand, offer much higher accuracy. They provide precise numerical readings, direct temperature readouts, often have built-in pressure-temperature charts for multiple refrigerants, and frequently include data logging capabilities. While more expensive upfront, their precision and advanced features can save significant time and prevent costly errors, especially for complex diagnostics. From my experience, the efficiency and accuracy gains from digital gauges often justify their initial investment by reducing troubleshooting time.

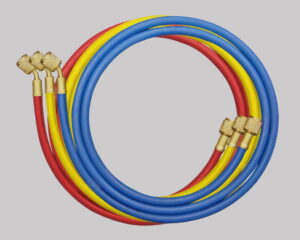

Finally, think about hose compatibility and quality. The hoses should be appropriately rated for the highest pressures you will encounter in any system you service. They should also be made of materials that resist refrigerant permeation, preventing loss over time. Always ensure the hoses have the correct fittings for your system, as different refrigerants may use different size ports (e.g., R-410A systems commonly use 5/16″ fittings, while R-22 often uses 1/4″). Using hoses equipped with ball valves at the ends can minimize refrigerant loss during connection and disconnection, further enhancing efficiency and environmental responsibility. A well-matched and high-quality set of hoses and gauges ensures safety and accuracy in your daily work.

Analog vs. Digital Gauges Comparison:

| Feature | Analog Gauges | Digital Gauges |

|---|---|---|

| Accuracy | Good, but prone to parallax errors and limited by needle resolution. | High, precise numerical readings with fine resolution. |

| Cost | Lower initial cost, generally more budget-friendly. | Higher initial cost due to advanced electronics. |

| Features | Simple pressure/temperature scales. | Multiple refrigerants, P/T charts, data logging, vacuum readout, superheat/subcooling calculation. |

| Durability | Very robust, no batteries, less sensitive to impact. | Can be sensitive to drops, requires batteries, sometimes less resistant to harsh environments. |

Which is better, 3-port or 4-port manifold gauges?

For HVAC/R work, 4-port manifold gauges are generally superior to 3-port sets, offering enhanced efficiency and comprehensive diagnostic capabilities. The additional port allows for simultaneous connection of a vacuum pump or recovery machine without the need to disconnect and reconnect service hoses, saving significant time and reducing refrigerant loss.

A 3-port manifold gauge typically has:

A 4-port manifold gauge adds an extra common service port, usually for a dedicated vacuum line. This means it has:

Features of 3-Port vs. 4-Port Manifolds:

| Feature | 3-Port Manifold | 4-Port Manifold |

|---|---|---|

| Service Ports | One shared service port (yellow) for all external connections. | Two dedicated service ports (one for refrigerant/recovery, one for vacuum). |

| Efficiency | Requires frequent hose swapping between recovery, evacuation, and charging. | Allows simultaneous connections, streamlining workflow, and reducing job time. |

| Versatility | Sufficient for basic pressure checks and simple charging/recovery. | Superior for comprehensive system diagnosis, faster recovery, and deep vacuum evacuation. |

| Cost | Generally less expensive due to simpler design. | Typically more expensive but offers long-term time savings. |

What should my AC manifold gauge read for optimal performance?

Optimal AC manifold gauge readings depend on the refrigerant type, ambient temperature, and system load. Generally, for a properly operating R-410A system, the low-side pressure should be 100-140 psi and the high-side 250-400 psi. Always refer to a pressure-temperature (P/T) chart specific to the refrigerant.

Understanding what your AC manifold gauges should read is crucial for accurate diagnostics. There is no single universal “correct” reading, as optimal pressures are highly dependent on several factors:

I also always look at superheat and subcooling measurements, which are calculated using the gauge readings and temperature measurements from a thermometer. These values provide crucial insights into the refrigerant charge and overall system efficiency saving significant time, minimizing potential for air or moisture to enter the system, and reducing refrigerant venting during transitions. For professionals who frequently perform full system services, from recovery to vacuuming and charging, a 4-port manifold significantly streamlines the workflow, making the overall process faster and more precise. I always recommend 4-port gauges for serious technicians who want maximum efficiency and diagnostic precision in their work.

Key Metrics for AC Manifold Gauge Diagnostics (R-410A, 85°F ambient):

| Metric | Typical Range (R-410A, 85°F ambient) | What it indicates |

|---|---|---|

| Low-Side Pressure | 100-140 psi | Evaporator performance, refrigerant charge, airflow issues |

| High-Side Pressure | 250-400 psi | Condenser performance, refrigerant charge, presence of NCGs |

| Superheat | 8-12°F (TXV), 10-20°F (Fixed Orifice) | Refrigerant charge, evaporator efficiency, metering device function |

| Subcooling | 8-12°F | Refrigerant charge, condenser efficiency, liquid line restrictions |

How to effectively use manifold gauges for diagnostics?

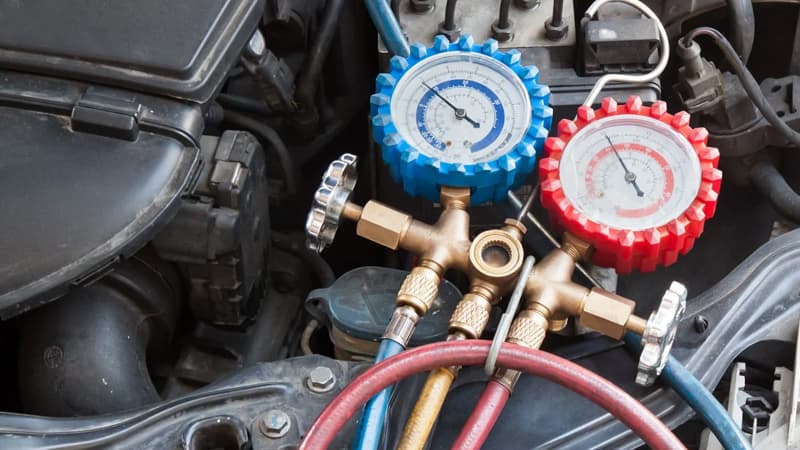

To effectively use manifold gauges for HVAC/R diagnostics, it is crucial to connect them correctly to the high and low-side service ports, purge the lines thoroughly, and monitor pressure readings in conjunction with a pressure-temperature chart and ambient conditions. Interpreting these readings holistically helps accurately assess refrigerant charge, identify restrictions, or detect compressor issues.

First, correct connection and purging are vital. Always connect the low-side hose (blue) to the suction line service port and the high-side hose (red) to the liquid line service port. The common service hose (yellow) connects to your vacuum pump, recovery machine, or refrigerant tank. Before opening the manifold valves to the system, it is crucial to purge the hoses to remove any trapped air. This involves slightly cracking the yellow hose at the manifold to allow a tiny puff of refrigerant to escape, effectively pushing out any trapped air. This prevents air from entering the sealed system, which, as I mentioned, can cause significant problems for performance and longevity.

Once connected and purged, monitor the readings while the system is operating steadily. Observe both the high-side and low-side pressures. Do they stabilize? Do they fluctuate erratically? Are they within the expected range for the given ambient temperature and refrigerant type? Always have your pressure-temperature (P/T) chart handy. Comparing the actual pressures to the saturated temperatures on the chart helps you calculate superheat and subcooling, which are critical diagnostic values. Superheat indicates if the evaporator is getting enough refrigerant and evaporating it completely. Subcooling tells you if the condenser is properly condensing the refrigerant into a subcooled liquid.

Furthermore, consider the ambient conditions (outdoor temperature) and indoor wet-bulb temperature. These environmental factors significantly influence what constitutes “normal” pressure readings. A seemingly “high” pressure reading on a very hot day might be normal, while the same reading on a mild day could indicate an overcharge or non-condensable gases. I always encourage technicians to record all relevant temperatures (indoor dry-bulb, indoor wet-bulb, outdoor dry-bulb, suction line, liquid line) alongside pressure readings. This holistic approach helps paint a complete picture of the system’s health, allowing for accurate refrigerant charge adjustments, identification of airflow problems, or detection of compressor inefficiencies. It is this combination of precise observation and thorough analysis that elevates you from a “gauge reader” to a true HVAC diagnostician.

Effective Manifold Gauge Usage Checklist:

| Step | Action | Purpose |

|---|---|---|

| 1. Connect Hoses Correctly | Blue to suction port, Red to liquid port, Yellow to service port. | Ensures proper access for pressure monitoring and system integrity. |

| 2. Purge Lines Thoroughly | Slightly open yellow hose to release refrigerant and push out air. | Removes air/non-condensables from hoses, prevents system contamination. |

| 3. Monitor & Record Data | Observe pressures, use P/T chart, record all relevant temperatures. | Gathers comprehensive data for accurate diagnosis and charge adjustment. |

| 4. Interpret Readings Holistically | Analyze superheat, subcooling, pressure ranges relative to ambient conditions. | Pinpoints issues like under/overcharge, restrictions, or compressor problems. |

Final Thoughts

- Coolink: TOP 3 Global HVAC Vacuum Pump Manufacturer

- Elitevak: Quality Industrial Vacuum Pump Supplier from China