This article is to introduce BLDC motor's applications, construction and advantages.

1. Applications

The brushless Direct Current motor (BLDC motor, also known as electronically commutated motor, ECM or EC motor) is increasing in its popularity in recent years. BLDC motors find applications in many industries, such as aircraft, automobiles, medical equipment, appliances, computer hard drives and power tools like battery powered vacuum pumps.

The BLDC motor is a type of synchronous motor. Among all types of 1-, 2- and 3-phase, the last one is the most popular motor in the market. For vacuum pumps, the motor range belongs to the motor ratings of 48 volts or less. 100 volts or higher rated motors are used in industrial applications.

2. Construction

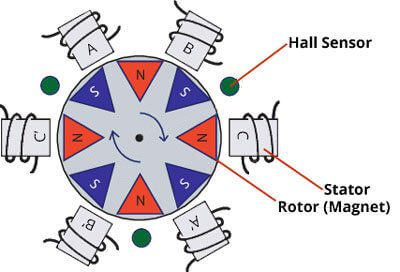

A BLDC motor has two basic components: the stator and the rotor. The stator of a BLDC motor is similar as that of an AC induction motor. The rotor however, is totally different. It’s made of permanent magnets (PM) which make the motor start easier and energy saving. The motor employs along with controllers, mostly Hall sensors (or Hall Effect Senor, three pieces for most of the BLDC motors), are embedded into the stator. In this way, the rotor position can be sensed by the electronic control circuit and the stator windings will be energized in a correct sequence.

3. Advantages

BLDC motors have many advantages over AC induction motors and also brushed DC motors:

- High efficiency due to PM motor (85-90%)

- Higher speed range and higher dynamic response

- High performance due to large torque

- Longer lifespan and low maintenance due to absent of carbon brushes

- Low operation noise

- Reduced motor size and lighter weight

- No sparking during operation

Among all advantages, large torque, small size, light weight and no spark operation are essential, which bring significant features to battery driven vacuum pumps like high performance operation, easy carry, convenient and safe use.

Coolink, a TOP 3 Global Quality HVAC Vacuum Pump Manufacturer from China