Refrigerant evacuation is crucial for the effective operation of heating, cooling, and refrigeration systems, where refrigerants are essential for transferring heat. This procedure is vital for preventing the adverse impacts of air, water, and nitrogen, which can reduce the efficiency of refrigerants and cause potential damage to the equipment. This article delves into the specifics of refrigerant evacuation, its appropriate timing, and its overarching importance for HVAC system maintenance.

Understanding Refrigerant Evacuation

The process of refrigerant evacuation involves the removal of moisture, air, and non-condensable gases from refrigeration systems. Achieved through the use of a vacuum pump, this method induces a vacuum state within the HVAC system, effectively ridding it of these harmful elements. The evacuation process encompasses two primary stages:

1. Degassing Stage

This initial stage focuses on swiftly removing air and vapor from the system.

2. Dehydration Stage

Here, the pressure is reduced by the vacuum pump to facilitate the evaporation of internal moisture. This stage demands careful execution to ensure a deep vacuum and a thoroughly sealed system.

When Is Refrigerant Evacuation Required?

HVAC technicians typically perform refrigerant evacuation in several scenarios:

- Prior to charging a new system with refrigerant.

- During installation of liquid and suction lines with open ends.

- Following system repairs that require opening the system.

- In cases of refrigerant loss due to leaks or during recovery processes.

Significance of Refrigerant Evacuation

The presence of unwanted substances like non-condensable gases and moisture in an HVAC system can significantly hinder its efficiency and lead to premature equipment failure. Non-condensable gases reduce the system’s condensation efficiency, leading to increased strain on the HVAC compressor. Moisture, on the other hand, can react with compressor oils to form corrosive substances or cause freezing in control circuits, disrupting air conditioning effectiveness.

Best Practices for Effective Refrigerant Evacuation

Ensuring a successful refrigerant evacuation involves adhering to specific best practices:

- Maintaining clean and debris-free conditions in fittings and refrigerant circuit components.

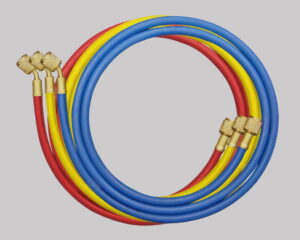

- Using large-diameter, short vacuum hoses for efficient evacuation.

- Regularly using clean oil in the vacuum pump and conducting routine maintenance checks.

- After reaching the target vacuum level, isolating and testing the system to ensure no leaks or moisture remain.

- Avoiding shortcuts that could lead to reduced system efficiency or early system failure.

In summary, keeping an HVAC system free from contaminants is vital for its efficient and long-term functioning. Properly executed refrigerant evacuation can significantly enhance system performance and extend the lifespan of these systems.

- Coolink: TOP 3 Global HVAC Vacuum Pump Manufacturer

- Elitevak: Quality Industrial Vacuum Pump Supplier from China