Best Ever China Oil-Sealed Screw Vacuum Pumps

15 years mature experience

following highest standards

Table of Contents

Quick access: Click & Jump directly to your desired section

TOP PICKS FOR YOUR NEEDS

Hot Products

EVS 450

- Max. flow rate: 426 m³/h

- Motor power: 5.5 kW

- Cooling type: Air cooling

- Noise level: 55 – 70 dB

- Weight: 700 kg

EVS 1300

- Max. flow rate: 1285 m3/h

- Motor power: 22 kW

- Cooling type: Air cooling/Water cooling

- Noise level: 55 – 76 dB

- Weight: 1050 kg

EVS 2000

- Max. flow rate: 1925 m3/h

- Motor power: 37 kW

- Cooling type: Air cooling/Water cooling

- Noise level: 65 – 79 dB

- Weight: 1500 kg

POPULAR INDUSTRIAL USE

General Applications

Semiconductor

CNC Machining

Food Packaging

Paper Printing

Woodworking

Clay & Brick Making

ADVANTAGES

Why Screw Pump

Smart Automation

Achieve peak operational efficiency with intelligent PLC and variable speed drive inverter (VSD).

Peak Performance

Crafted with robust construction and advanced technology to meet highest industry standards.

Energy Efficiency

Save on significant energy costs with our high-efficiency IE4 PM motor.

Quiet Operation

Enjoy a noise-free environment with operations as low as 55 dB.

Remote Monitoring

Effortlessly monitor your pump status remotely by using a PC, Pad or Smartphone.

EXPLORE EXCELLENCE INSIDE

System Breakdown

Screw Vacuum Pump

- Twin-screw design with high reliability, high efficiency and low noise

- Absolute no leak due to non-shaft design at inlet

- Maximum ultimate pressure of 0.3 mbar

PM Electric Motor

- IE4 motor with super premium efficiency up to 97%

- IP55 enclosure, protection from dirt, dust and water

- Integrated PTC thermal protector inside motor winding

PLC and Inverter

- Smart operation due to PLC, vector power inverter and PM motor

- High efficient and durable INOVANCE inverter inside

- 6″ color touch screen

Cooling System

- High efficient with low noise

- Specially designed cooler controls pressure drop with sufficient load redundancy

- Thermostatic valve and sensor ensure proper working temperature

Inlet Filter

- Pre-filter design with 99% filtering efficiency @5 Micro

- Easy replacement of filter elements

- Polyester material available for vapory application

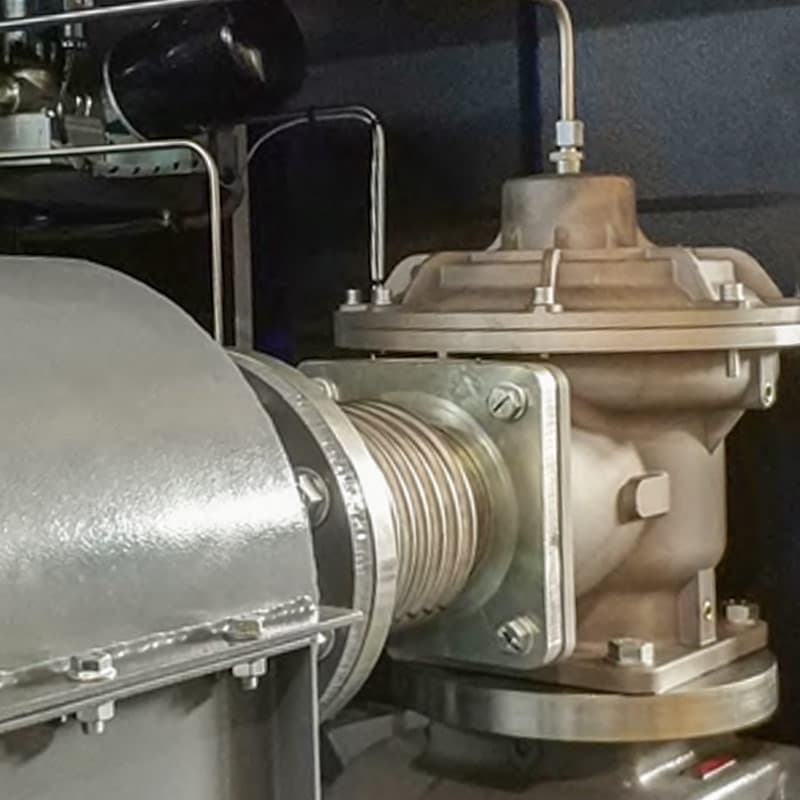

Inlet Control Valve

- Super low pressure differential improves pump efficiency

- The pump can operate at 500 mbar(a).

- External actuator or additional compressed air not required

Oil Separator

- Ultra-low oil exhaust, less than 3 ppm

- Small exhaust back pressure and power consumption due to super low separation pressure drop

- Optimized filter elements

Noise Reducer

- Soundproof fan in the box

- Thicker steel plate and sound absorbing foam efficiently isolate the noise

- Noise level as low as 55 dB(a).

Full Synthetic Oil

- Enhances vacuum pump performance

- High temperature resistance

- Ideal for vapor-intensive applications

YOU SHOULD KNOW

Some Basic Knowledge

Oil-lubricated screw vacuum pumps excel in rough vacuum industrial applications, operating efficiently between atmospheric pressure and 100 Pa (1 mbar) – a range typically defined as a rough vacuum.

For medium and high vacuum applications, a vacuum pump (such as a dual stage rotary vane pump) is connected with a sealed vacuum chamber. It’s used to maintain the pressure in the chamber. In such a closed system, a pump model can be easily selected based on the nominated ultimate pressure of the pump.

Absolutely. Oil-sealed vacuum pumps are a perfect fit for central vacuum systems, particularly replacing multiple older pumps with a single EVS model, which results in a quieter, more efficient, and stable system.

For instance, one EVS 950 can replace three rotary piston pumps, and two EVS 1800 can substitute for five water ring pumps, saving energy and space even in smaller facilities.

The primary benefit is energy efficiency. While many pumps claim to be energy-saving, not all utilize IE4 super premium efficiency motors – some don’t even meet the IE2 standard.

Our oil screw vacuum pumps are designed with top-tier motors with VSD technology (Variable Speed Drive) for maximum energy savings. You may save up to 50% on energy costs compared to alternative mechanical vacuum pumps with fixed speeds.

Industries that demand reliability, efficiency, and continuous operation, such as semiconductor & electronics, aerospace components, thermoforming, printing, woodworking, food processing, high altitude simulation as well as central vacuum systems, find great value in our oil-sealed rotary screw vacuum pumps.

Indeed, our competitor has a few versions like standard, humid and turbo.

We offer one versatile standard version that can be tailored to different working conditions by simply adjusting parameters and switching oils. For instance, in vapor-rich environments like brick making, switching to full synthetic oil from standard mineral oil is effective and incurs minimal additional cost.

We prioritize adapting our standard model to your specific needs without extra charges.

History of Oil Screw Vacuum Pump

1980

Quincy Compressor launched the world’s first oil-sealed rotary screw vacuum pump, later expanding to China with a new Kunshan factory in 2004.

2010

The acquisition of Quincy by Atlas Copco led to a merged technological prowess, enabling them to maintain the new market dominance for over a decade.

2019

Everblue, established by Quincy’s ex-chief engineer and a veteran R&D team, rapidly emerged as a market leader in China, outshining industry giants with superior technology.

YOUR PARTNER WITH PROVEN SOLUTIONS

Why Choose Us

Patented Precision

Each product is meticulously crafted to the highest standards.

Pioneering Performance

Our advanced solutions align perfectly with your specific needs.

Cost-Effective Excellence

Enjoy superior quality without high price tag, thanks to our efficient production.

Extensive Range

With 12 models, find the perfect fit for your varied flow rate requirements.

OEM Service

We’re open to provide private labelling.

TESTIMONIALS

What Our Clients Say

THE LATEST PROJECT ACHIEVEMENTS

Project Cases and Plant Tour

Projects

Industry | Chip Packaging

Industry | Semiconductor

Industry | Woodworking

Industry | CNC Machines

Industry | Printing

Industry | Brick Manufacturing

Plant Tour

R&D Center

System Testing

Assembly Workshop

QUICK ORDER STEPS

Ordering from Us

Step 1 | Choosing Your Model

Pick the right model(s) and quantity for your project. Everblue offers complimentary proposals to guide your selection.

Step 2 | Initiating Production

Kickstart the manufacturing process with a 30% deposit based on the agreed-upon proforma invoice.

Step 3 | Arranging Shipment

Expect your shipment to be dispatched once production wraps up in about 3 weeks and the remaining 70% balance is settled.

Step 4 | Guided Setup and Activation

Benefit from our engineer’s expertise for seamless on-site installation and commissioning, ensuring any technical hiccups are swiftly addressed.

SELECT YOUR DESIRED MODELS

Technical Data

| Model | Flow Rate (m³/h) |

Ultimate Pressure (mbar) |

Motor Power (kW) |

Noise (dB) | Inlet Connection |

Outlet Connection |

Weight (kg) |

|---|---|---|---|---|---|---|---|

| EVS 450 | 426 | 0.3 | 5.5 | 55-70 | G2 1/2 | G2 | 700 |

| EVS 550 | 545 | 0.3 | 7.5 | 55-70 | G2 1/2 | G2 | 700 |

| EVS 750 | 727 | 0.3 | 11 | 55-70 | DN100 | DN80 | 700 |

| EVS 950 | 963 | 0.3 | 15 | 55-74 | DN100 | DN80 | 1050 |

| EVS 1100 | 1112 | 0.3 | 18.5 | 55-76 | DN100 | DN80 | 1050 |

| EVS 1300 | 1285 | 0.3 | 22 | 55-76 | DN100 | DN80 | 1050 |

| EVS 1800 | 1751 | 0.3 | 30 | 65-79 | DN150 | DN100 | 1500 |

| EVS 2000 | 1925 | 0.3 | 37 | 65-79 | DN150 | DN100 | 1500 |

| EVS 3000 | 3052 | 0.3 | 45 | 67-80 | DN200 | DN150 | 3200 |

| EVS 3900 | 3863 | 0.3 | 55 | 67-80 | DN200 | DN150 | 3200 |

| EVS 4800 | 4870 | 0.3 | 75 | 72-85 | DN200 | DN150 | 5500 |

| EVS 5600 | 5632 | 0.3 | 90 | 72-85 | DN200 | DN150 | 5500 |

| EVS 6200 | 6181 | 0.3 | 110 | 72-85 | DN200 | DN150 | 5500 |

FREQUENT QUESTIONS & ANSWERS

FAQs

For distributors, we offer a 12-month warranty for the entire system and an extended 24-month warranty for the rotary screw vacuum pump, starting from the sea shipment’s Bills of Lading date.

For other shipping methods, the warranty begins from the day we dispatch it from the factory.

Typically, we take about 4 to 6 weeks. But if we have everything ready in stock, we might get it to you in just 2 weeks!

We’re open to provide OEM service at the moment, in condition that the name of Everblue is mentioned as the provider on the machine.

Everblue is the most experienced and top-tier rotary screw vacuum pump manufacturer in China. As its strategic partner, Elitevak manages all export activities efficiently.

We prefer wire transfers (T/T) – 30% upfront and the balance before we ship your order. If we’re racing against time and the lead time is under 3 weeks, we’d appreciate full payment upfront. It just helps speed things up!

Get Your Free Project Proposals Today!